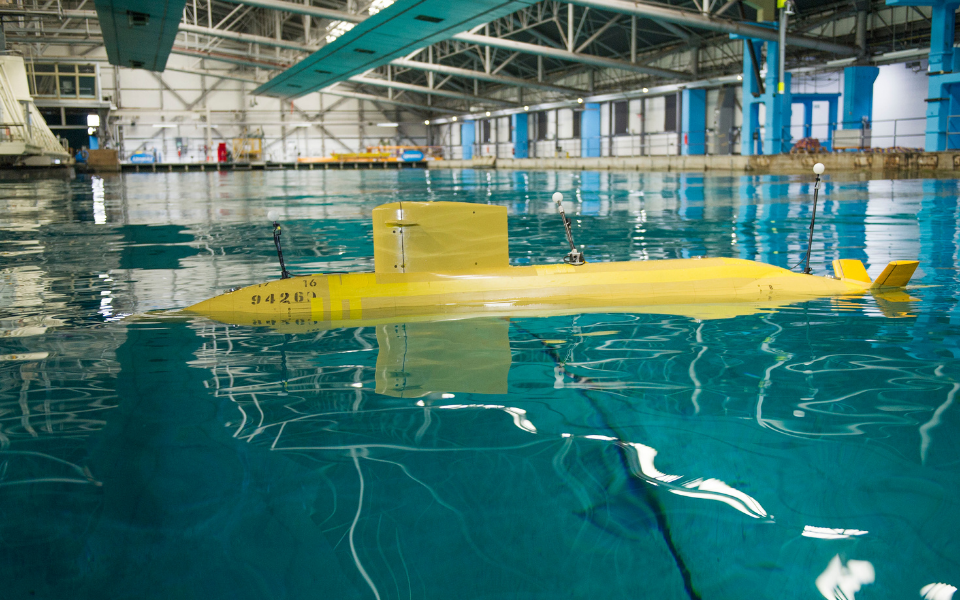

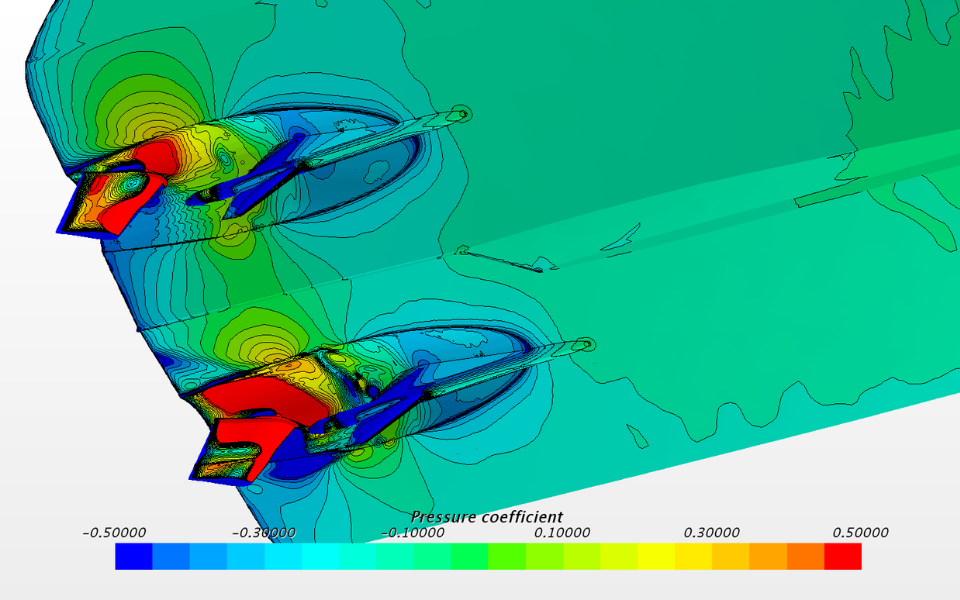

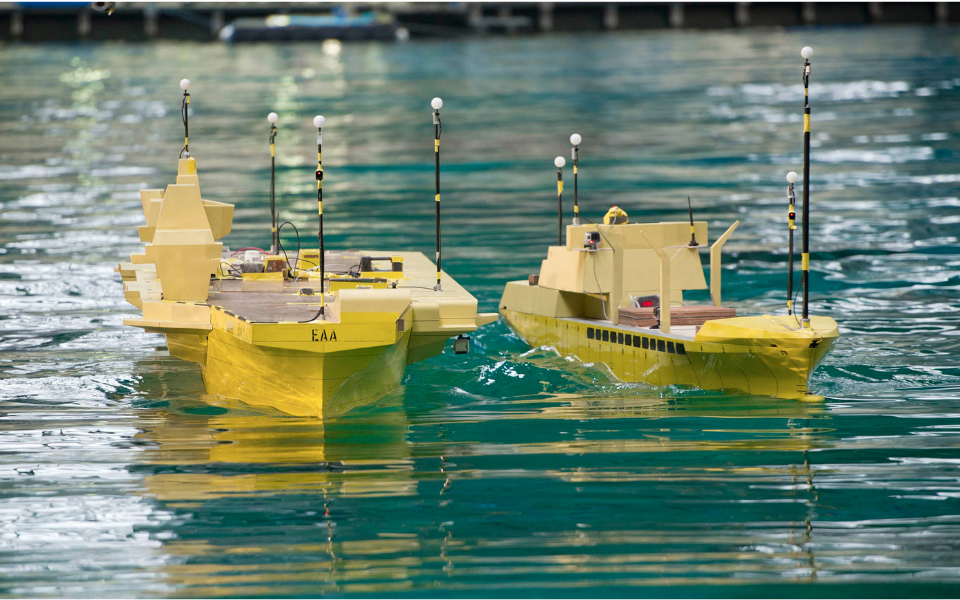

QinetiQ delivers bespoke solutions that deliver novel, unique and exceptional outcomes in all areas of ship & submarine design, hydrodynamic testing and technical consultancy. With access to a large and diverse team of specialists as well as over £100million of advanced test facilities and equipment, our defence and commercial maritime customers know that we will deliver operational, technical and competitive advantage.

Our hydrodynamic heritage spans no less than 150 years. We continue to build on this legacy and experience with an ongoing investment in new capabilities and resources. Today, we have one of the world’s largest hydrodynamic facilities as well as multiple high performance computing clusters for assessing, optimising and reviewing vessel designs and new concepts from a safety, hydrodynamic, human and operational perspective.

Our services include:

- Performance Assessment of in-service and feasibility level vessel designs.

- Design Optimisation of feasibility level vessel designs.

- Concept Development to define or review solution architecture for vessel requirements.

- Safety & Capability Assessment of through-life vessel changes.